With the development of industry 4.0 and the promotion of intelligent manufacturing, unmanned chemical plants have sprung up, robots have become more and more popular to replace artificial labor, the production efficiency is constantly improving, and the commodity production capacity is greatly enhanced. At the same time, with the development of the Internet and the rise of e-commerce, As a result, the modern logistics industry is developing towards intelligent logistics and intelligent warehousing. Unmanned three-dimensional intelligent warehouse is stepping into the era of 2.0 from 1.0.

The management of the safe use of shelves in the process of using shelves depends on the visual management of on-site operators or regular inspection and inspection by professional personnel. The obvious disadvantage of this method is the lack of timeliness. Visual management can only be found when the shelf is tilted or even collapsed. Regular inspection needs to organize human and material resources to reduce the detection cycle In order to grasp the shelf tilt in time. Based on this, it is necessary to provide a set of timely monitoring and detection of shelf tilt status of equipment.

At present, most of the equipment and systems for tilt detection are RS232 / RS485 / TTL Cable connection interface and cable power supply. If these tilt detection devices are applied to monitor and detect the tilt of the shelf, it is necessary to re wire the warehouse in order to transmit the data of the tilt acquisition equipment and provide external power supply to it. This wiring increases the difficulty of deploying the tilt detection equipment, and at the same time, it needs to provide external power for the tilt detection equipment on the shelf Source power supply increases the risk of electricity safety. In addition, the tilt detector on the market does not provide tilt overrun alarm function, which is not suitable for long-term detection and monitoring of shelf tilt.

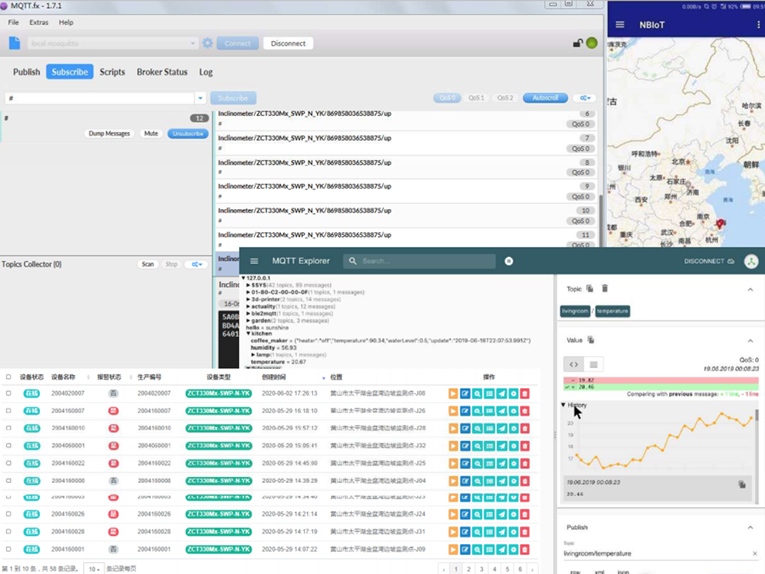

Zhichuan technology has been committed to the R & D and production of inclination sensors for nearly 20 years. we have entered the field of intelligent storage earlier. In 2018, Zhichuan technology took the lead in using the Internet of things nb-iot tilt sensor (ZCT330MX‐SWP‐N‐YK) and platform in Yili Group, the largest dairy products leading enterprise in China, to monitor the safety of warehouses all over the country. In the follow-up, the shelf nb-iot wireless tilt monitoring systems are adopted by Coca Cola, Qingdao FAW,Golden dragon fish intelligent warehouse and other more three-dimensional warehouses, and gain high evaluation and full affirmation from customers.

ZC nb-iot tilt sensor is based on nb-iot (its model is zct330m-swp-n-yk), which can be fixed on the shelf at four corners to monitor the angle change of the shelf in an all-round way, and the local deformation and inclination that cannot be observed by naked eyes can be displayed in real time through the Internet of things cloud platform or mobile app software. On the one hand, it can timely detect and replace the shelf with quality problems that have been deformed; on the other hand, When the sensor is vibrated after opening the defense, and the movement angle exceeds the set alarm angle, the sensor will wake up and send alarm information.

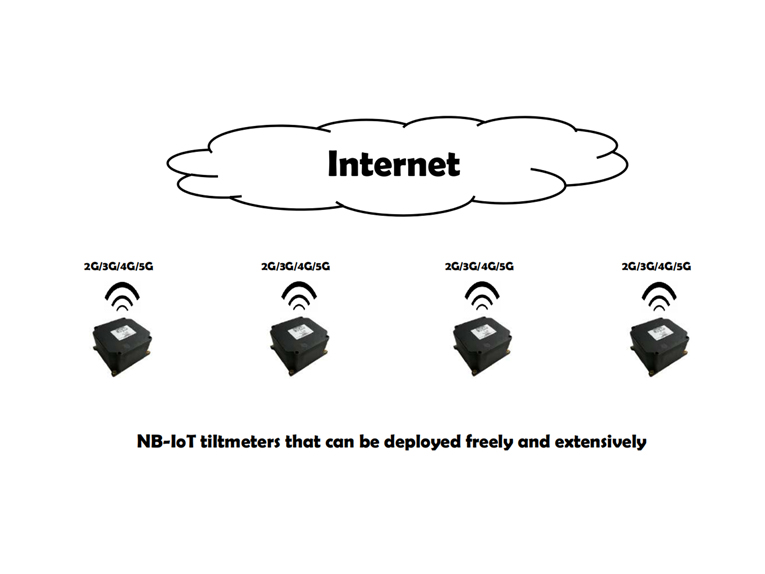

NB–IoT tiltmeters that can be deployed freely and extensively, It has:

- SIMPLE: Simplest topology, no gateway or repeater required

- FREE: No worries on number of connections or signal coverage

- EXTENSIVE: Based on 2/3/4/5G, can be deployed across a large area

- RELIABLE: Outstanding communication reliability, ultra-low packet loss rate

- ACCURATE: High resolution and repeatability, temperature drift compensated

- RUGGED: Watertight metal housing, Lithium battery for year round use

- POWER-SAVING: Low power consumption, heartbeating at set interval only

- REASSURED: Alarm automatically upon a tilt threshold that is pre-set

- USER-FRIENDLY: Open-source tools available for building up broker/client